|

|

Wide range of Internal Pipe Blaster’s and Coaters are available from CLEANBLAST™ and choice can be made as per your pipe internal diameter. Application includes cleaning of pipes and tubes for removing mill scales, rust, paint coatings, dust contaminants etc. Attached to the blast hose end of a standard blasting pot, the operator manually or with a semi-automatic winch system withdraws internal pipe blast attachment though the length of the pipe at a contact speed based on the required blast standard. |

| |

|

CLEANBLAST™Internal Pipe Blaster

Super Mini TuBlast

The smallest internal pipe blaster has an exchangeable tungsten carbide deflection head which lets out the abrasive from one side. The head of the Super Mini Tublast is capable of entering pipes of just 13mm. With extension pipes the deflection head can be attached to an adaptor nozzle with ¾" BSP or 50mm coarse thread.

The extension pieces can be delivered with 250, 500, 750 or 1000mm length.

Description |

Art No |

CLEANBLAST™ Super Mini Tublast |

B30010 |

|

|

| |

|

Mini Tublast

The small internal pipe blaster has an exchangeable tungsten carbide deflection tip which spreads the abrasive in 360º. The Mini Tublast is capable of blasting pipes with internal diameters of 30 to 100mm.

It only fits ½ blast hose which can be ordered at required lengths.

Description |

Art No |

CLEANBLAST™ Mini Tublast for pipes of ID 30 to 100mm |

B30015 |

|

|

| |

|

Tublast

The Tublast internal pipe blaster has a exchangeable tungsten carbide deflection tip with spreads the abrasive at 360º. An internal nozzle of 13 or 16mm can be selected. It’s delivered with various centring collars for small pipe diameters and a centring carriage for blasting larger diameters pipes. This carriage can easily be set to fit different pipes. The Tublast has a standard blast hose coupling connection and can efficiently blast pipes with internal diameters of 70 to 295mm.

Description |

Art No |

CLEANBLAST™ Tublast c/w carriage for pipes of ID 70 to 295mm |

B30030 |

|

|

| |

|

Rotoblast

The Rotoblast has a rotating head which is driven by the force of the compressed air escaping the two nozzles. It has a break system to avoid excessive trunign speads of the head. Different tungsten carbide nozzles can be chosedn depending on the piple diameters and compressed aie capacitites. Boron cardide nozzles are available on request.

The centring carriage comes with different lengths so it fills all diameter s between 210 and 890mm.

Description |

Art No |

CLEANBLAST™ Rotoblast complete with carriage for pipes of ID 210 to 890mm |

B30300 |

|

|

| |

|

Jumbo Rotoblast

The Jumbo Rotoblast is the biggest model of the series. It has an extra large rotation head which is driven by the force of the compressed air escaping from the two nozzles. It has a break system to avoid excessive turning speeds of the head.

Different long venture shaped tungsten carbide nozzles can be chosen depending on compressed air capacities. Boron carbide nozzles are available on request.

The legs of the centering carriage can be set to fit diameters of pipe between 890 and 1600mm.

Description |

Art No |

CLEANBLAST™ Jumbo Rotoblast complete with carriage for pipes of ID 890 to 1600mm |

B30310 |

|

|

| |

|

Semi-Automatic Winch System

The semi –Automatic winch system is specially developed for the Tublast & (Jumbo) Rotoblast but can be used with pipe coaters. The winch has a strong motor and is PLC Controlled. It pulls at the blast hose with an adjustable but constant speed from almost zero to 3 meters per minute giving a constant and reproducible result. A switch is mounted to stop the motor when the unit has cleaned or coated the surface.

Description |

Art No |

CLEANBLAST™ Semi-Automatic Winch system |

B30320 |

|

|

| |

|

CLEANBLAST™ Internal Pipe Coater (IPC).

CLEANBLAST™ IPC Pipe Coater is designed to coat the inside of pipe or tubing. The machine having a rotating head powered by an air motor, throws paint by centrifugal force at an evenly metered flow against the surface. The CLEANBLAST™ IPC Pipe Coater unit needs to be attached or coupled to airless painting machine of min 45:1 ratio and is manually pulled through the pipe at a pre-determined speed based on paint film thickness and type of coating. The paint will be pumped from an airless painting system though the paint hose and it gets atomized by the speed of the rotation head by centrifugal force and sprayed onto the internal wall of the pipe.

CLEANBLAST™ IPC designed to produce a uniform layer of paint at remarkable speed and is easy to operate and maintain. Typical coating rates of 10 lineal feet per minute (3m/min) are obtained for most types of paint.Generally, any type of coating may be used in this tool that can be airless sprayed. To obtain the best possible production, one man should operate the paint Spray Gun while another man pulls the tool through the pipe or tubing.

The IPC-models have a spraying tip inside to give a controlled flow of paint material and that you can change in different size. Be sure to check with the coating manufacturer or supplier on the size spray tip to be used for applying the type of coating specified. Spray tip sizes used on IPC is normally lager than tip sizes used for Hand spraying applications. Improper spray tip may effect speed and paint thickness. All Pipe coaters are supplied with a standard tip.

Description |

Art No |

CLEANBLAST™ Pipe Coater IPC 125

IPC-125 has a spraying head with diameter off 54mm and is designed for coating inner diameters of 3" until 5" (76mm – 125mm) |

P73010 |

Description |

Art No |

CLEANBLAST™ Pipe Coater IPC 300

IPC-300 has a spraying head with diameter off 69mm and is designed for coating inner diameters of 5" until 12" (125mm – 300mm) |

P73020 |

Description |

Art No |

CLEANBLAST™ Pipe Coater IPC 900

IPC-900 has a spraying head with diameter off 69mm and is designed for coating inner diameters of 12" until 35" (300mm – 900mm) |

P73030 |

Description |

Art No |

CLEANBLAST™ Pipe Coater IPC 300/900

IPC-300/900 has a spraying head with diameter off 69mm and is designed for coating inner diameters of 5" until 35" (125mm – 900mm) |

P73060 |

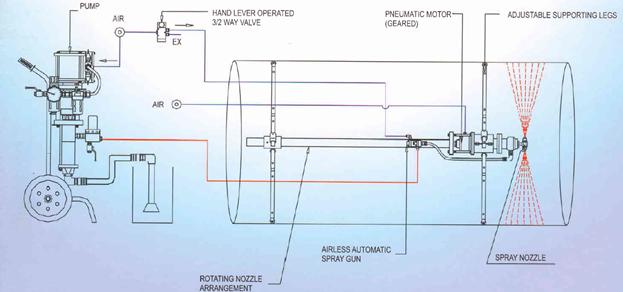

Airless Jumbo Internal Pipe Coater

Airless Jumbo Internal Pipe Coaters are suitable for high performance high build single/two component coating application. It uses a rotating nozzle airless system for pipe internal diameters from 500mm and above upto 2.5meters.

Description |

Art No |

CLEANBLAST™ Airless Jumbo Internal Pipe Coater

Designed for pipe’s internal diameters of 500mm until 2.5metrs |

P73023 |

|

| |

|

Airless External Spray Pipe Painting

When it comes to external pipes coatings, CLEANBLAST™ will be your right supplier for airless type of external pipe painting systems. We have solutions for pipes which are moving on conveyers with fixed spraying ring as well as for old pipes laid on or under the ground with oscillating automatic spraying ring.

Description |

Art No |

CLEANBLAST™ Airless Fixed Spray Rings for External pipe coatings

|

P73021 |

CLEANBLAST™ Airless Oscillating Spray Rings for External pipe coatings |

P73022 |

|

|

| |

|